前言

試驗機是在各種條件、環境下測定非金屬材料、金屬材料、機械零件、工程結構等機械性能、工藝性能、內部缺陷并校準精密儀器旋轉部件的動不平衡,對材料可進行拉伸、壓縮、 彎曲、剪切、扭轉、沖擊、疲勞、蠕變和持久、松弛、磨損、硬度測試等。 在對新材料、新技術、新技術和新結構工藝的研究和探索中,試驗機是不可缺少的重要測試儀器。 本文對基本定義、研究背景和意義、國內外一些重要廠家的分類和成果進行了概述。 第二部分論述了滾珠絲杠-錐齒輪、滾珠絲杠-鏈傳動、滾珠絲杠-直齒傳動和液壓傳動四種傳動方案,并進行了對比分析,最后選擇滾珠絲杠-錐齒輪傳動系統作為本文的設計對象。 第三部分對試驗機的主要機械傳動部分,如電機、滾珠絲杠傳動系統、錐齒輪傳動系統、減速器、軸和軸承、無級變速器等部分進行了選型,詳細的設計計算,經過校核后所有的設計均符合要求。

Testing machine is under various conditions, environment determination of non-metallic materials, metal materials, machinery parts, engineering structure, such as mechanical properties, process performance, internal defects and calibration precision instrument rotating components of the dynamic unbalance, the material can be tensile, compression, bending, shear, torsion, impact, fatigue, creep and lasting, relaxation, wear, hardness test, etc. In the research and exploration of new materials, new technology, new technology and new structure of the process, testing machine is an indispensable important test instrument. In this paper, the basic definition, research background and significance, classification and achievements of some important manufacturers at home and abroad are summarized. The second part discusses the ball screw - bevel gear, ball screw - chain transmission, ball screw - spur gear and hydraulic drive four transmission schemes, and comparative analysis, finally choose the ball screw - cone gear transmission system as the design object of this paper. The third part of the main mechanical transmission parts of the testing machine, such as motor, ball screw drive system, bevel gear drive system, reducer, shaft and bearing, CVT and other parts of the selection, detailed design and calculation, after checking all the designs are in line with the requirements.

研究背景及意義

材料試驗機是在各種條件、環境下確定金屬材料、非金屬材料、機械零件、工程結夠精密旋轉部件機械性能、工藝性能、內部缺陷及動不平衡檢測儀器材料可以拉伸、壓縮、彎曲、剪切、扭轉、沖擊、疲勞、蠕變、耐久性、松弛、磨削 、損傷、硬度測試等。 在研究和探索新材料、新技術、新工藝和新結構的過程中,試驗機是一種是不可缺少的重要測試儀器。 廣泛應用于機械、冶金、石油、化工、建材、建筑、航空 航天、造船、交通等工業部門和大學、研究所相關實驗室。 有效地使 使用材料,改進工藝,提高產品質量,降低成本,確保產品安全可靠等。

Material testing machine is in various conditions, the environment to determine metal materials, non-metallic materials, mechanical parts, engineering knot Precision testing instrument for mechanical properties, process properties, internal defects and dynamic unbalance of rotating parts, The material can be stretched, compressed, bent, shear, torsion, impact, fatigue, creep, durability, relaxation, grinding Damage, hardness test, etc. In the research and exploration of new materials, new technology, new technology and new structure of the process, testing machine is a An indispensable and important test instrument. Widely used in machinery, metallurgy, petroleum, chemical, building materials, construction, aviation Aerospace, shipbuilding, transportation, and other industrial sectors and universities, research institutes related laboratories. To effectively make Use material, improve process, improve product quality, reduce cost, ensure product safety and reliability, etc.

國內材料試驗機的現狀

我國的計量檢測事業歷史悠久,但在舊中國的試驗機制造業是空白的,中華人民共和國建國后,黨和工商局高度重視測量測試技術的發展,采取了許多重要措施來發展儀器鐘表業。 經過50多年的努力,我國萬能材料試驗機的制造,從無到有,從小到大單參數到多參數,從靜態到動態,逐步發展到初步規模化,隨著生產的靜載試驗機(如拉力壓力萬能試驗機、扭轉試驗機、松弛試驗機、耐久強度試驗機、蠕變試驗機、復合試驗機力試驗機等)和動載荷試驗機(如沖擊試驗機和疲勞試驗機等)的能力得到有效提升,發展國民經濟建設和國防建設。 我國萬能材料試驗機市場已形成集量程、試驗機于一體的格局

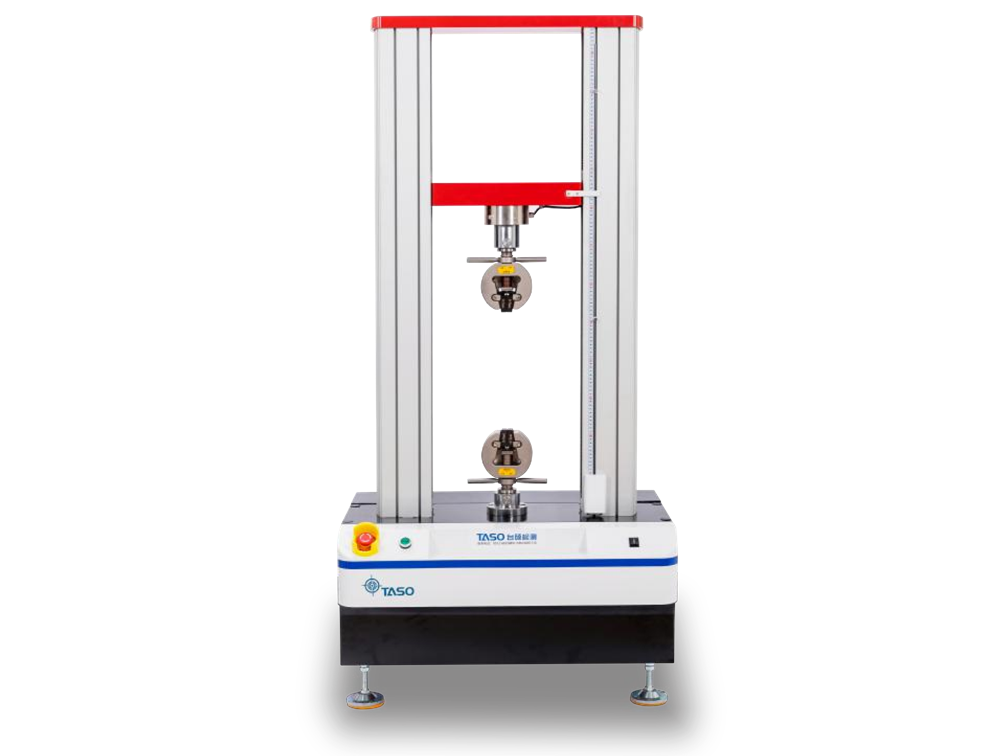

產品的開發日趨規模化、智能化、動靜態功能復雜,部分試驗機產品已遠銷國外, 出口到亞洲及歐美市場,具有一定的競爭力。 電子萬能材料試驗機(雙柱落地式)如圖1-1所示,主要用于金屬和非金屬材料 拉伸、壓縮、彎曲等力學性能測試與分析。 可以自動獲取 ReH、ReL、Rp0.2、Fm、Rt0.5、Rt0.6、RT0.65、Rt0.7、Rm、E等試驗參數,并可根據

GB、ISO、DIN、ASTM、JIS等國際標準進行測試并提供數據。 電子萬能試驗機(雙柱落地式)性能特點:電子萬能試驗機(雙柱落地式)具有高強度 燈桿固定在上橫梁和工作面上,形成高度剛性的門式框架結構。 伺服電機驅動, 伺服電機通過傳動機構驅動運動梁上下運動,實現試驗加載過程。 分為單空間和雙空間 兩個模型。 主機采用先進的DSCC-1全數字閉環控制系統進行控制和測量,采用計算機控制動態顯示試驗過程和試驗曲線,并對數據進行處理,試驗結束后可進行圖形處理

塊曲線放大用于數據再分析和編輯,產品性能已達到國際先進水平。 Waw-100液壓萬能試驗機如圖1-2所示。 它的程序由一個開放的數據庫結構定義。 符合GB228-87標準。 GB/ T228-2002、GB7314-87等試驗方法,也可根據用戶要求定制 特殊的測試方法。 測量方法采用高精度壓力傳感器、高精度位移傳感器、高線性度低 混合信號處理與放大模塊,試驗材料力學性能人機交互分析與計算,試驗接頭自動計算彈性模量、屈服強度、非比例延伸應力,在自動分析的基礎上,也可以進行人工校正分析結果,提高分析的準確性。 液壓萬能試驗機可配備材料試驗機的閉環控制和數據采集電液控制器(可選) 根據客戶要求配置進口控制器,如:DOLI),它具有強大的功能,叉性都非常優秀能源價格比率。 適用于科研單位、高等院校、質量監督部門和檢測中心進行檢測、科研、仲裁和使用特殊測試的需要。

China's measurement and testing business has a long history, but the testing machine manufacturing industry in the old China is blank, the People's Republic of China After the founding of China, the Party and the government attached great importance to the development of measurement and testing technology, and adopted many important measures to develop instruments Watch industry. After more than 50 years of efforts, China's universal material testing machine manufacturing, from scratch, from small to large Single parameter to multi-parameter, from static to dynamic, gradually developed into a preliminary scale, with the production of static load testing machine (such as Tension and pressure universal testing machine, torsion testing machine, relaxation testing machine, durable strength testing machine, creep testing machine, composite testing machine Force testing machine, etc.) and dynamic load testing machine (such as impact testing machine and fatigue testing machine, etc.) ability to effectively promote Development of national economic construction and national defense construction. China's universal material testing machine market has formed - set scale, testing machine The development of products is becoming increasingly large-scale, intelligent, dynamic and static functions of the complex, some testing machine products have been exported to foreign countries, Exported to Asia and Europe and The United States market, with a certain competitiveness. Figure 1-1 shows the electronic universal material testing machine (double column floor type), which is mainly used for metal and non-metal materials Tensile, compression, bending and other mechanical properties testing and analysis. It can be obtained automatically ReH, ReL, Rp0.2, Fm, Rt0.5, Rt0.6, RT0.65, Rt0.7, Rm, E and other test parameters, and can be based on GB, ISO, DIN, ASTM, JIS and other international standards to test and provide data. Electronic universal testing machine (double column floor type) performance characteristics: electronic universal testing machine (double column floor type) with high strength The light bar is fixed to the upper beam and the work surface to form a highly rigid portal frame structure. Servo motor driven, The servo motor drives the moving beam to move up and down through the transmission mechanism to realize the test loading process. Divided into single space and double space Two models. The main machine adopts advanced DSCC-1 full digital closed-loop control system for control and measurement, and adopts computer Dynamic display of the test process and test curve, and data processing, after the end of the test can be processed by graphics Block curve amplification for data re-analysis and editing, product performance has reached the international advanced level. Waw-100 hydraulic universal testing machine is shown in figure 1-2. Its program is defined by an open database structure. In line with the standard GB228-87. GB/ T228-2002, GB7314-87 and other test methods, can also be customized according to user requirements Special test method. The measurement method uses high precision pressure sensor, high precision displacement sensor, high linear low Hybrid signal processing and amplification module, human-computer interaction analysis and calculation of mechanical properties of test materials, test junction Automatic calculation of elastic modulus, yield strength, non-proportional extension stress, on the basis of automatic analysis, can also be Manual correction of analysis results to improve the accuracy of analysis.

Hydraulic universal testing machine can be equipped with closed loop control and data acquisition for material testing machine electro-hydraulic controller (available According to customer requirements to configure imported controller, such as: DOLI), it has a powerful function, fork both very excellent sex Energy price ratio. Applicable to scientific research units, universities, quality supervision departments and testing centers for testing, scientific research, arbitration and The need for special tests.

客服1

客服1